For decades, the realm of high-torque bolting—the tightening of critical fasteners in demanding environments—was an arena exclusively reserved for Bulky, loud, and complex hydraulic or pneumatic systems. These tools required cumbersome hoses, external power units, and intricate maintenance Schedules. Today, that era is ending. The modern Industrial Cordless Nut Runner has arrived, bringing with it a revolution in portability, precision, And compliance for tasks requiring torque well above 2000Nm 1500ft-lbs-

The most immediate and transformative advantage of the Heavy Duty Cordless Torque Wrench is its complete freedom from external power sources. Imagine maintenance crews working on a distant wind turbine, high up on an offshore platform, or deep within a mining facility. In these scenarios, Dragging air hoses or hydraulic lines is not just inefficient—it’s a major safety liability and a logistical nightmare.

The Battery Torque Wrench delivers its massive power entirely from an integrated, high-capacity lithium-ion power pack. this allows technicians to Deploy rapidly, eliminate trip hazards, and significantly reduce job setup time. When time is money, and safety is paramount, this Hydraulic Wrench Alternative is the clear choice .we are not sacrificing power for portability; we are combining Industrial Power with Unmatched Portability.

The strength of these tools goes far beyond the battery. Modern Cordless Torque Wrenches are engineering marvels built for continuous, high-cycle applications:

At the core of these reliable tools is the Brushless Motor. Unlike older brushed motors, which lose energy to friction and require frequent carbon replacement, the brushless design delivers torque with superior efficiency and a longer lifespan. For a High Torque Cordless Wrench, this means less heat build-up during sustained use, longer periods between charging, and minimal maintenance—a critical factor for fleet managers seeking to reduce total cost of ownership.

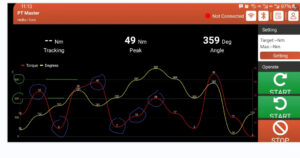

Gone are the days of relying on analog gauges and best-guess settings. every high-end Digital Battery Torque Wrench offers precise control over the Bolting process. operators can use the Adjustable Torque Settings to dial in the exact specification required, with the Digital Displays providing real-Time torque readings. this ensures consistent application, reducing the risk of structural failure from incorrectly fastened bolts. accuracy is essential, And our tools typically operate within a tight toleranc

In industries such as oil and gas, infrastructure, and aerospace, proving that a fastener was tightened correctly is often as important as the tightening itself. Our tools address this through advanced Data Logging capabilities.

Models equipped with built-in memory systems automatically store all critical bolting data—including torque applied, angle turned, and time of Completion. this provides a transparent, tamper-proof digital audit trail. this feature ensures your operation meets strict regulatory standards and Maintains NIST Traceability, certifying that your fastening results are nationally and internationally recognized as accurate. this functionality transforms The wrench from a simple tool into a sophisticated quality assurance device.

The power range of 1500Nm-10,000Nm {75-6000 ft-lbs} positions these tools perfectly across several high-growth, heavy-duty sectors:

Wind Energy Bolting: Fastening tower sections and blade components requires immense, certified torque. The portability of the cordless wrench dramatically cuts the time needed to service or erect turbines.

Commercial Vehicle Maintenance: Changing the lug nuts on large transport trucks, buses, or heavy machinery requires tools capable of 1500ft-lbs or more. our Heavy Duty Cordless Torque Tools make quick work of these tasks, significantly speeding up fleet service times.

Infrastructure and Construction: From setting bridge spans to assembling modular buildings, the need for safe, documented tension on large fasteners is constant. The cordless unit ensures that quality control is simple and mobile.

When selecting your next High Torque Cordless Wrench, prioritize the features that matter most to your bottom line: ft-lbs capacity (to match the American standard), Data Logging, and the presence of a Brushless Motor.

Moving away from antiquated pneumatic and hydraulic systems isn’t just an upgrade; it’s an investment in safety, efficiency, and verifiable precision. Embrace the freedom and power of the modern Industrial Cordless Nut Runner and redefine what’s possible in high-torque bolting.

Accuracy Guaranteed: Understanding Calibration for Your High-Torque Cordless Wrench The

Why High Torque Cordless Wrenches are Replacing Hydraulic Tools The