Why High Torque Cordless Wrenches are Replacing Hydraulic Tools

The demand for high-power bolting solutions in industrial settings—from mining and infrastructure to commercial vehicle maintenance—has traditionally been dominated by cumbersome hydraulic or pneumatic systems. However, a new generation of Heavy Duty Cordless Torque Wrenches is rapidly shifting the industry standard, offering $2000 Nm-1500 ft-lbs and beyond, without the cables or pumps.

The core advantage of the cordless electric wrench is true mobility. Hydraulic systems, while powerful, require a separate pump, hoses, and dedicated power sources—making the whole setup heavy, slow to deploy, and a major safety hazard due to tripping risks.

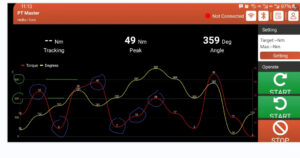

Our Cordless Torque Wrenches eliminate this complexity. They deliver peak, NIST Traceable power right out of the case. This is crucial for remote field jobs, where Wind Energy technicians or infrastructure crews need to tighten critical bolts rapidly and accurately without hauling heavy, complex auxiliary equipment across the job site.

The advanced technology inside these tools ensures performance that often surpasses their predecessors:

If your team is still relying on slow, noisy, and complicated hydraulic or pneumatic systems for high-torque applications, it’s time to upgrade. A High Torque Cordless Wrench is not just a replacement; it’s an upgrade to efficiency, safety, and modern, certified precision.

Accuracy Guaranteed: Understanding Calibration for Your High-Torque Cordless Wrench The

For decades, the realm of high-torque bolting—the tightening of critical